Molded Sponge Rubber, Molded Foam Rubber, or Molded Cellular Rubber

Whether you call it Cellular, Foam or Sponge Rubber; Colonial DPP has manufactured over four billion (4,000,000,000) of these custom molded seals and gaskets for the world’s major industries. Molded cellular rubber is a chemically-blown rubber that can be formulated for open or closed cell applications.

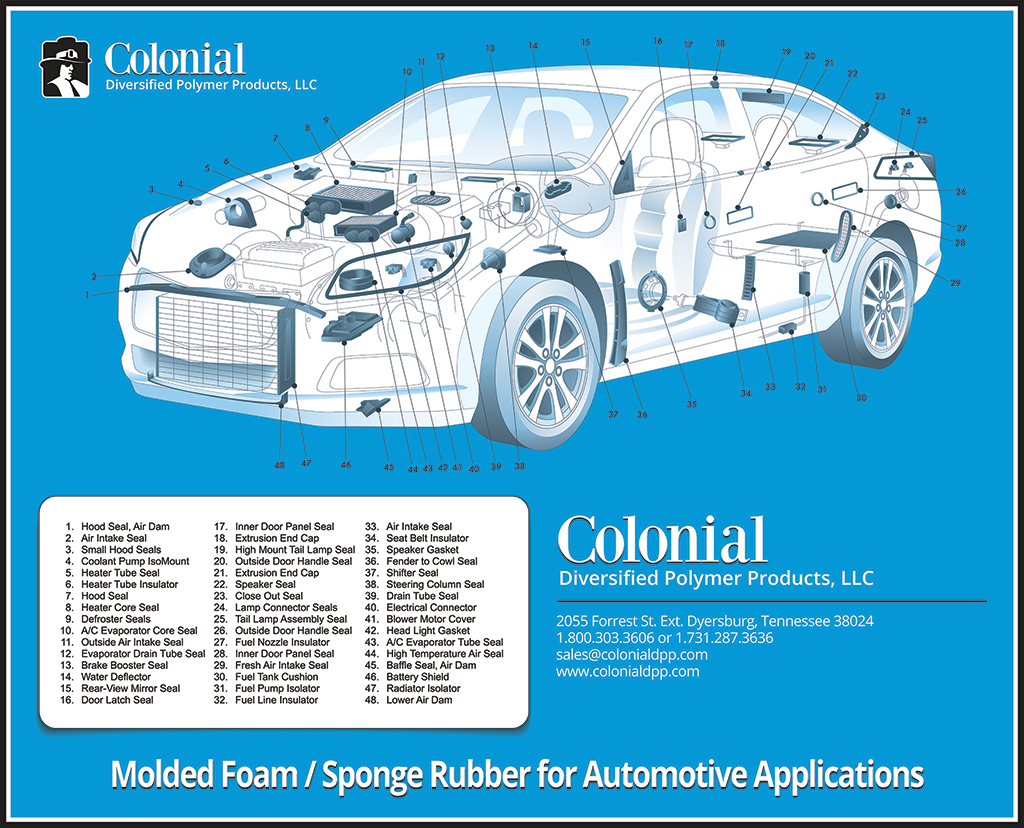

Colonial’s molded products add value for our customers by employing a multi-level one piece seal that efficiently replaces built-up and two material die cut seals. Foam rubber can create a leak-proof barrier against noise; vibration, dust, water and other fluids, when open cell urethane foam and ethylene materials under perform. Sponge rubber also has superior tear strength and withstands extreme temperature swings when compared with competing materials. Cellular rubber maintains superior sealing performance when stack up conditions vary from assembly to assembly; it may be necessary to compress the same part 25% on one assembly and 50% on another.

Our extensive lab and formulating capabilities enable Colonial to design and compound materials to meet a vast range of physical properties including resistance to chemicals, high heat, and extreme weather conditions. Density can be adjusted to create very soft or firm seals.

Materials include but are not limited to: EPDM; Neoprene; SBR; Nitrile; rubber to metal bonding; and rubber to plastic bonding.